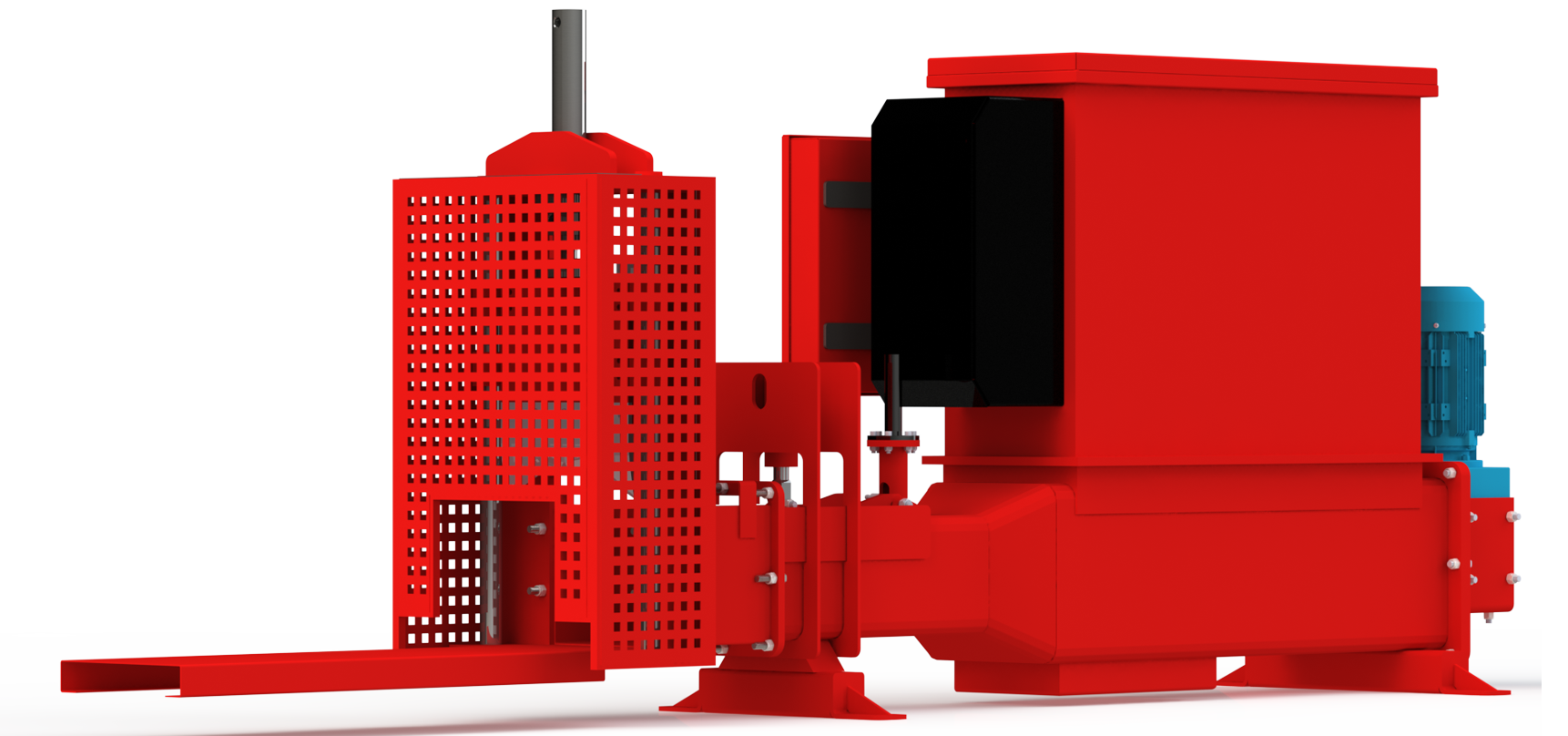

MK9 EPS Static

Shark MK9 EPS Static is specifically developed to shred and compress expanded polystyrene (EPS), also known as foam, and solves all known challenges when processing EPS materials.

The MK9 Static EPS is equipped with the well-known, innovative technologies and safety components that characterize all Shark products, including the advanced Shark Intelligent Control™ (SIC™).

SIC™ is a unique control system designed to meet the specific requirements of compacting recycled materials such as EPS. It makes operation extremely user-friendly by reducing operator effort to a minimum – only one push of a function button is required.

The system continuously measures temperatures, pressure levels and the density of the compressed EPS, and it automatically adjusts performance to achieve optimal results based on the selected density settings.

The Shark MK9 Static EPS offers a groundbreaking solution that improves the efficiency of EPS handling, reduces labor costs and promotes more sustainable waste treatment.

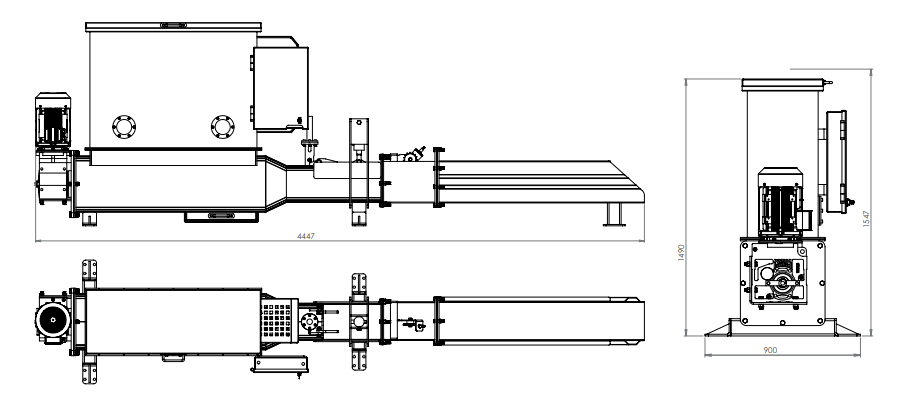

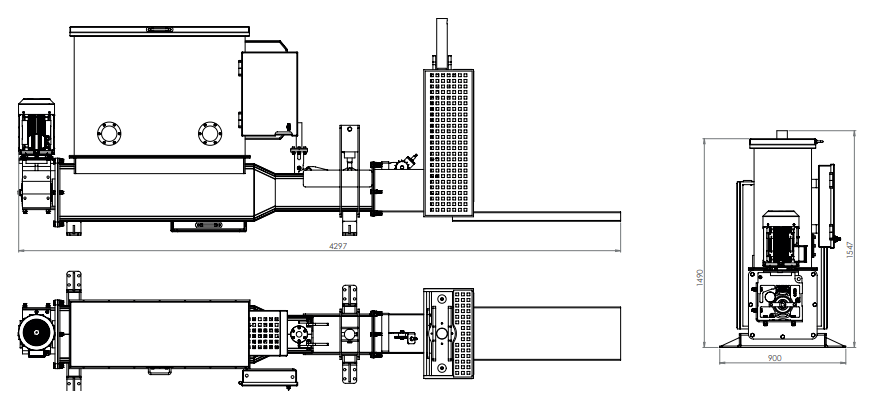

MK9 EPS Static - Specifications

Properties

Technical information

-

Engine type Electric motor

-

Press capacity (per hour) 40 kg

-

Press capacity (per day) 275 kg

-

Current 3 * 400 v 50 hz 16 Amp.

-

Pressed block dimension 150 * 150

-

Empty total weight 800 kg.

-

Product brochure

Shark Compactors MK9 EPS Static Compactor

The Shark MK9 Static EPS Compactor is a brand new and most innovative product from Shark Compactor for recycling businesses.

The MK9 Static EPS also features renowned Shark creative technologies and safety components like all Shark products.

Shark MK-9 Static EPS provides unique EPS (Expanded Polystyrene Foam) shredding and compaction system to solve all known major problems for EPS materials.

The MK9 Static EPS also features renowned Shark creative technologies and safety components like all Shark products.